CONTACT INFO

Contact:Mss Wang

Address: TaiZhou City, JiangSu Province, Lift District ,China

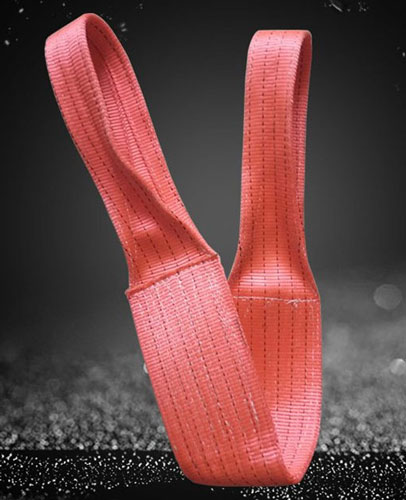

What is the maximum load capacity of a 5 Tonne webbing sling?

Webbing slings are widely used in various industries for lifting and securing heavy loads. When you come across a "5 Tonne webbing sling," it's natural to wonder about its actual maximum load capacity. This article aims to provide a comprehensive understanding of what the 5 - tonne specification means and the factors influencing the sling's load - bearing ability.

Defining the 5 - Tonne Rating

Nominal Capacity

A 5 - tonne webbing sling is designed with a nominal load - capacity rating of 5 metric tons (or 5,000 kilograms). This rating represents the maximum safe working load under ideal conditions. Ideal conditions typically include proper sling usage, correct attachment to the load and lifting equipment, and a suitable working environment.

Working Load Limit (WLL)

The 5 - tonne figure is essentially the Working Load Limit (WLL) of the sling. The WLL is determined by the manufacturer after conducting a series of tests and calculations. It takes into account the strength of the webbing material, the design of the sling (such as the type of stitching and end - fittings), and a safety factor. The safety factor is incorporated to ensure that the sling can withstand loads greater than the WLL under normal operating conditions, providing an extra margin of safety.

Factors Affecting the Maximum Load Capacity

Sling Configuration

The way the webbing sling is configured during lifting can significantly impact its load - bearing capacity. For example, a vertical lift (where the sling is attached directly above the load) allows the sling to carry its full rated capacity. However, if the sling is used in a choker or basket hitch, the load distribution changes, and the effective load capacity may be reduced. In a choker hitch, the capacity might be around 80% - 90% of the vertical - lift capacity, depending on the angle and other factors.

Angle of Lift

The angle at which the sling is used relative to the load also affects its maximum load capacity. As the angle between the sling legs decreases (in a multi - leg sling setup), the tension in each leg increases. This means that for a given load, the effective capacity of the sling per leg is reduced. Manufacturers usually provide angle - load capacity charts to help users determine the safe load based on the lifting angle.

Condition of the Sling

The overall condition of the webbing sling is crucial. Any signs of damage, such as cuts, abrasions, fraying, or chemical degradation, can weaken the material and reduce its load - bearing capacity. Regular inspections are necessary to identify and address any issues promptly. If a sling shows significant damage, it should be taken out of service immediately to avoid safety risks.

Environmental Factors

The working environment can also influence the sling's performance. Exposure to extreme temperatures, chemicals, UV radiation, or moisture can degrade the webbing material over time. For example, high - temperature environments may cause the webbing to lose its strength, while chemical exposure can lead to corrosion or weakening of the fibers. In such cases, the maximum load capacity may need to be adjusted or the sling may need to be replaced more frequently.

Ensuring Safe Use of a 5 - Tonne Webbing Sling

Training

All personnel involved in using the webbing sling should receive proper training on its correct usage, including how to calculate the load based on the configuration and angle, how to inspect the sling for damage, and how to attach it safely to the load and lifting equipment.

Inspection

Regular inspections are essential. Before each use, the sling should be visually inspected for any signs of damage. Periodic in - depth inspections by a qualified person are also recommended to ensure the long - term integrity of the sling.

Compliance

Ensure that the webbing sling complies with relevant industry standards and regulations. This includes standards related to material quality, manufacturing processes, and safety requirements.

Conclusion

In summary, a 5 - tonne webbing sling has a nominal maximum load capacity of 5 metric tons under ideal conditions. However, various factors such as sling configuration, angle of lift, sling condition, and environmental factors can affect its actual load - bearing ability. By understanding these factors and following proper safety procedures, users can ensure the safe and effective use of the 5 - tonne webbing sling in their lifting operations.